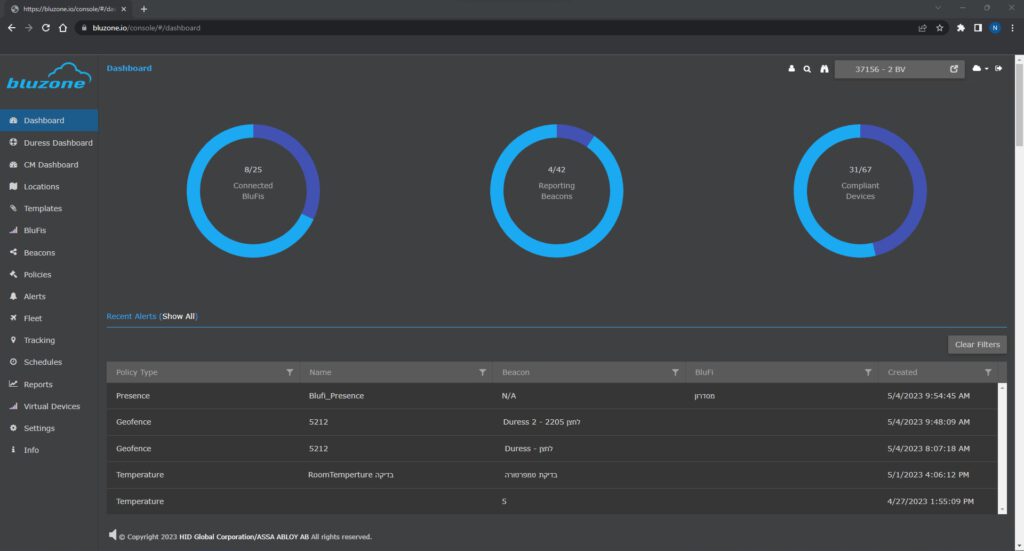

The BluVision system we offer provides a solution for monitoring the operating status, health, and status of equipment. The system allows maintenance managers in a factory or organization to streamline their maintenance policies and switch from a break-fix maintenance policy to a predictive maintenance policy.

Some of our beacons are equipped with advanced sensors that can transmit, in addition to location data, also status data such as temperature and vibration (3-axis acceleration). These sensors provide values for measuring trends in equipment behavior changes, which can be used to alert for possible future failure, such as a temperature rise to a dangerous range.

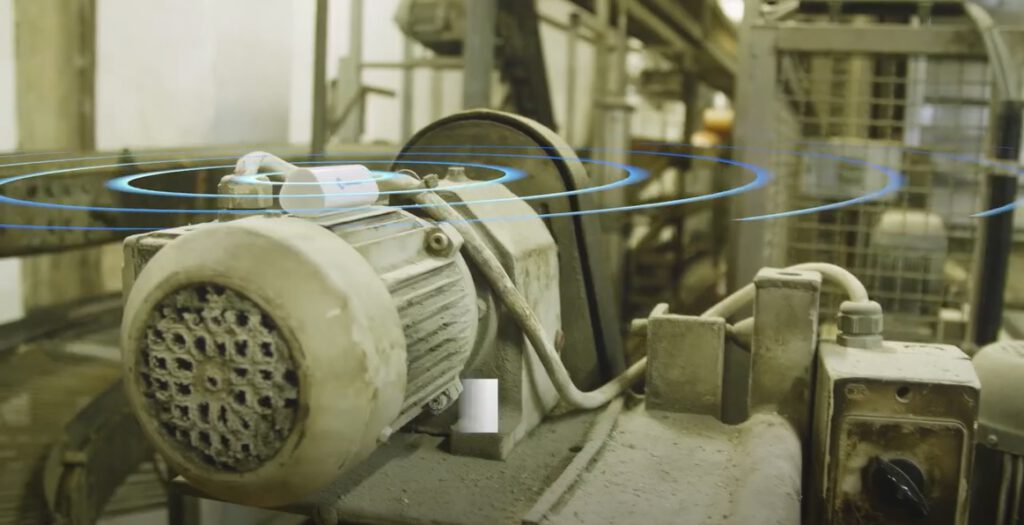

A decrease in output or a conveyor belt shutdown is one of the biggest threats to production units. The BluVision system is capable of monitoring the health of motors and motorized equipment such as conveyors and lifting units by monitoring vibration and temperature data and understanding the trend relative to each monitored equipment. An AI learning system can be activated for each motor or rotating equipment and learn the unique behavior of that motor, so after the learning period the system can alert for an anomaly in the motor behavior that may indicate a failure in the making.

BluVision’s Condition Monitoring solutions are product and equipment agnostic and can be easily attached to any beacon on any type of surface and equipment. The BluZone cloud management environment will be able to provide alerts and notify the appropriate team when the system detects an expected failure. Moreover, it is possible to perform analyzes in different slices to learn about trends and predict failures in advance.